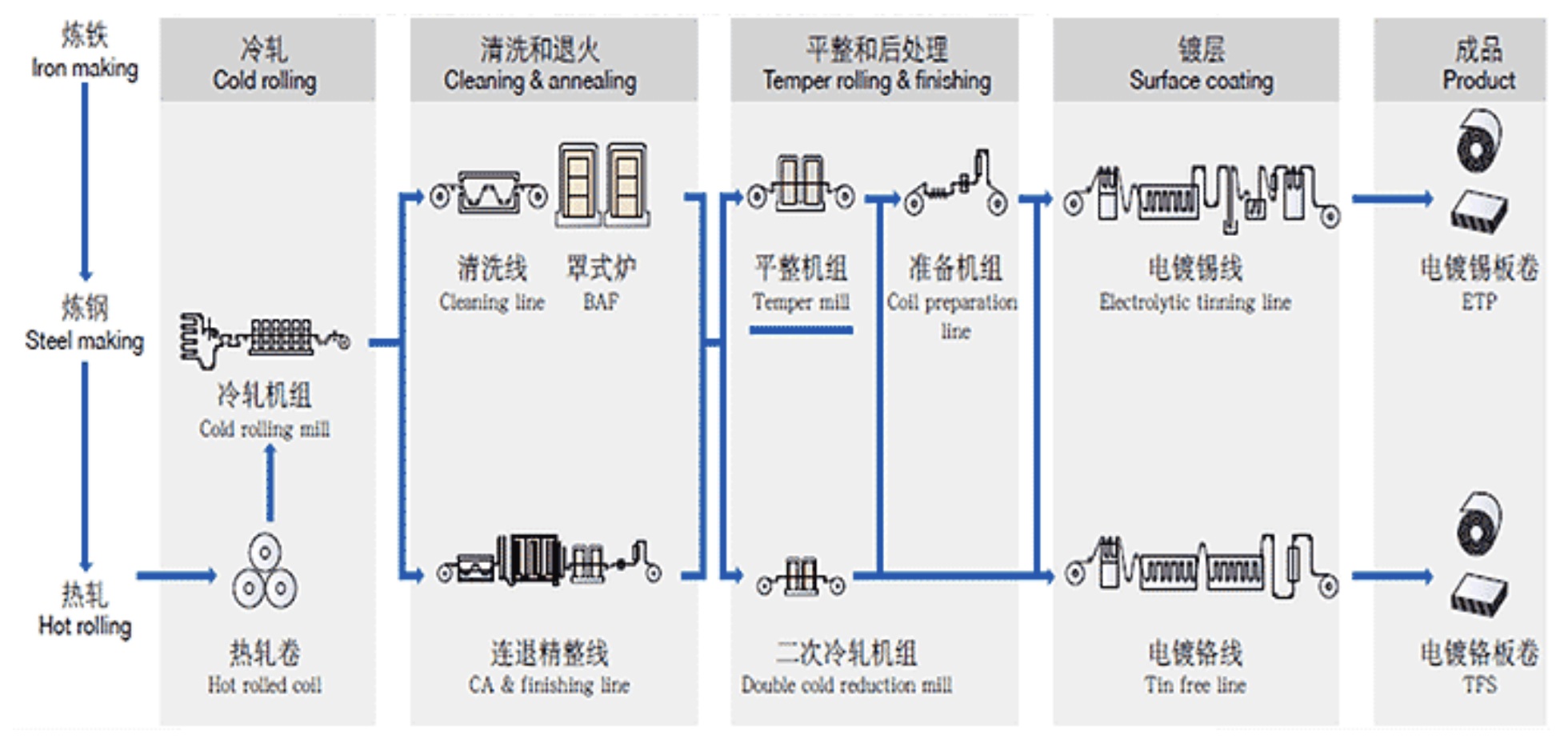

Tin-Free Steel (TFS) – Introduction

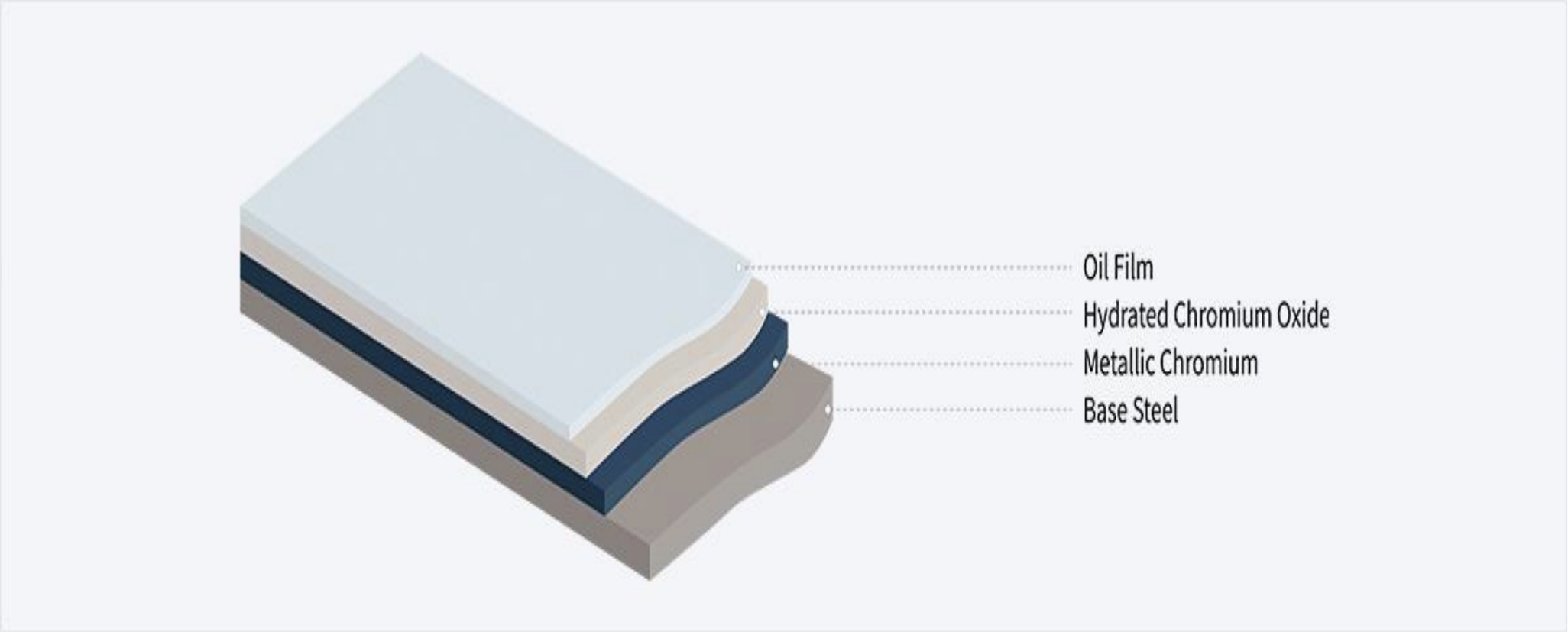

Tin-Free Steel (TFS) is a type of steel sheet that is coated with a layer of chromium or chromium oxide as an alternative to traditional tinplate (steel coated with a layer of tin). The primary purpose of this coating is to protect the steel from corrosion, especially in applications where the steel will come into contact with food or other liquids, like in the production of cans, packaging, and containers. While tinplate has traditionally been used in food packaging, TFS offers similar corrosion resistance and formability but with several advantages, including a different environmental impact and ease of recycling.