Tinplate – Introduction

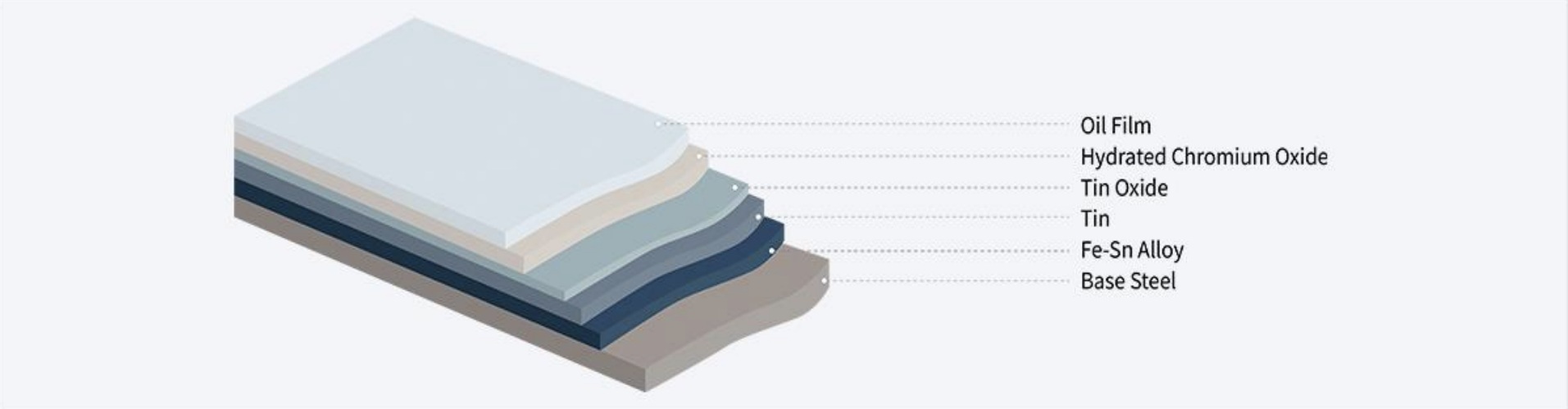

Tinplate is a type of steel sheet that is coated with a thin layer of tin to provide corrosion resistance. It is commonly used in applications where protection from rust, durability, and safety (such as food preservation) are important. Tinplate has been used for over a century, primarily in the packaging industry for food cans, beverage containers, and other packaging products. Its corrosion resistance, excellent formability, and ability to be welded and soldered make it an ideal choice for these applications. The tin coating on the steel provides a barrier against moisture, acids, and other corrosive elements, which helps preserve the contents of cans and ensures the safety and longevity of the products. Additionally, tinplate is fully recyclable, making it a popular choice for environmentally-conscious manufacturers.

Mechanical Characteristics of Tinplate

The mechanical properties of tinplate are critical for its use in manufacturing applications where it must withstand mechanical stresses, such as bending, forming, and handling. Below are the typical mechanical characteristics of tinplate:

- Yield Strength

- Definition: The yield strength is the stress at which a material begins to deform plastically (permanently).

- Typical Value: Tinplate has a yield strength typically in the range of 180 to 300 MPa, depending on the grade and thickness. This ensures it can withstand the mechanical forces of deep drawing and other forming processes without permanent deformation.

- Tensile Strength

- Definition: The tensile strength is the maximum amount of stress that a material can endure before it breaks or fractures.

- Typical Value: The tensile strength of tinplate generally ranges from 300 to 600 MPa, depending on the thickness and type of steel used. This high tensile strength is crucial for applications where the material must endure mechanical stress without failing.

- Elongation

- Definition: Elongation measures the ability of a material to stretch or elongate before breaking, which is an important property for forming processes.

- Typical Value: Tinplate typically exhibits 10% to 30% elongation (depending on the grade), indicating good ductility. This is essential for deep drawing and stamping processes in canning and packaging industries.

- Hardness

- Definition: Hardness refers to a material's resistance to surface indentation or scratching. For tinplate, this is important for maintaining the integrity of the surface in packaging and handling.

- Typical Value: The hardness of tinplate usually ranges from 50 to 70 HRB (Rockwell B scale). This indicates moderate hardness, ensuring the material resists surface damage during manufacturing and use.

- Formability

- Definition: Formability refers to the ability of a material to undergo shaping processes (such as stamping, deep drawing, or rolling) without cracking or breaking.

- Typical Value: Tinplate has excellent formability, typically characterized by an n-value (strain hardening exponent) around 0.2 to 0.3. This indicates that tinplate can undergo significant deformation during can-making or other forming processes without failure.

- Modulus of Elasticity

- Definition: The modulus of elasticity (also known as the elastic modulus) is a measure of a material's stiffness—how much it will stretch or compress under a given force.

- Typical Value: The modulus of elasticity for tinplate is around 200 to 210 GPa. This high value indicates that tinplate is relatively stiff and will not deform excessively under applied loads.

- Impact Toughness

- Definition: Impact toughness measures a material's ability to absorb sudden impacts without fracturing.

- Typical Value: Tinplate is designed to withstand moderate to high impacts without breaking or cracking, making it suitable for applications that involve handling, transportation, and storage. Impact toughness can vary based on the specific grade and thickness.

- Bendability

- Definition: Bendability refers to the material's ability to bend without cracking or breaking, important for applications such as can making.

- Typical Value: Tinplate has good bendability, allowing it to be shaped without cracking or losing integrity. This property is especially important in the canning industry.