At Zhuoyi Steel Group, we understand that exceptional products require exceptional tools for exceptional quality. Our commitment to excellence extends beyond the material itself—it begins at the source. We proudly partner with leading international producers of tinplate, tin-free steel (TFS), and aluminum, all of whom operate with the most advanced production and processing equipment available in the industry today, ensuring that every order we handle reflects precision, consistency, and the highest industry standards.

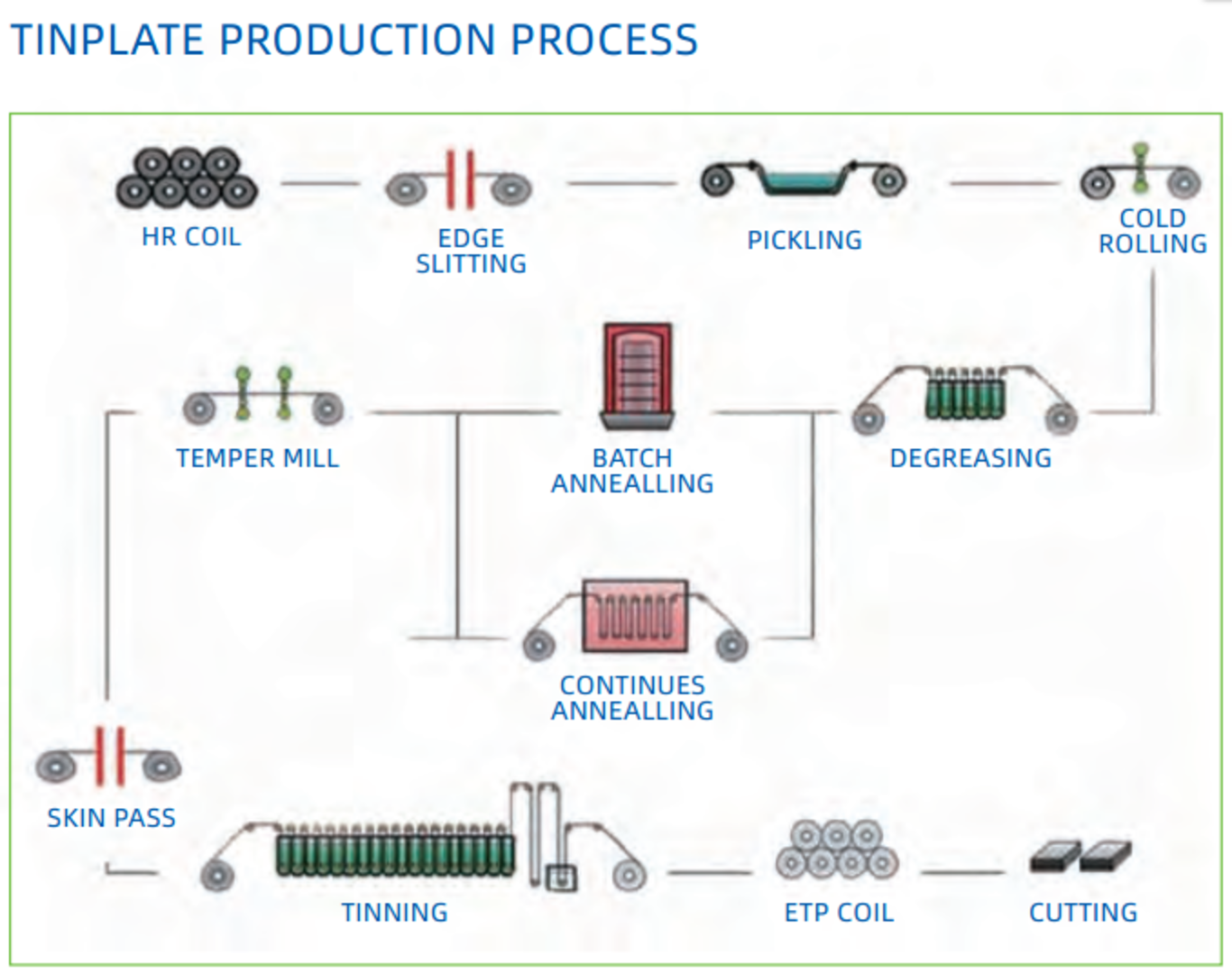

Our partners employ state-of-the-art electrolytic tinning lines, electrolytic chromium coating lines (ECCS/TFS), and high-speed aluminum cold rolling and finishing mills, ensuring outstanding surface finish, uniformity, durability, gauge control, and metallurgical consistency. The facilities also feature double-reduction rolling mills for enhanced strength and formability, continuous annealing lines, automated slitting and shearing systems, and precise tension leveling equipment, all of which contribute to exceptional product performance.

It is this level of technical sophistication and continuous upgrades that allows us to meet evolving global standards in food grade and packaging applications, combined with an uncompromising approach to quality control to consistently deliver material that meets the most demanding performance and compliance requirements.

These technological and quality standards are not only a reflection of our producers’ capabilities—they are a direct extension of Zhuoyi Steel Group’s own commitment to delivering trusted, high-performance material for packaging and consumer applications.